In the realm of electronics manufacturing, achieving the perfect balance between cost efficiency and quality is paramount. As technology evolves and market demands shift, manufacturers face increasing pressure to deliver high-performance products while keeping production costs in check. One innovative solution that has emerged to address this challenge is the integration of complimentary generic components offered by PCB Power. In this blog post, we’ll explore how leveraging these components can unlock significant benefits in terms of cost savings, enhanced quality, and accelerated production cycles.

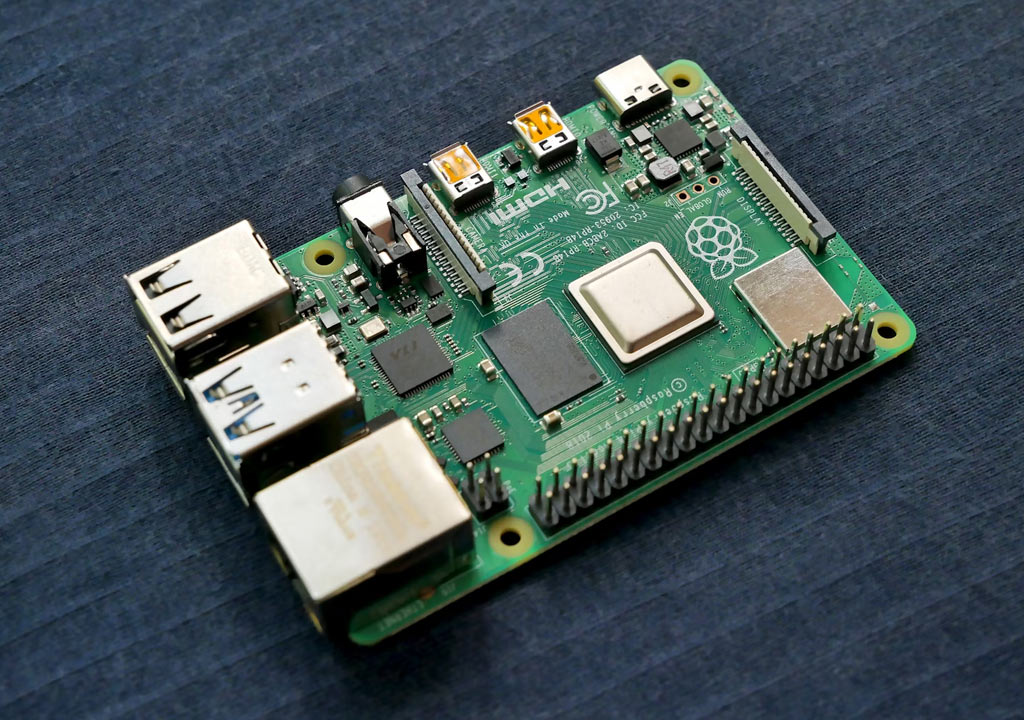

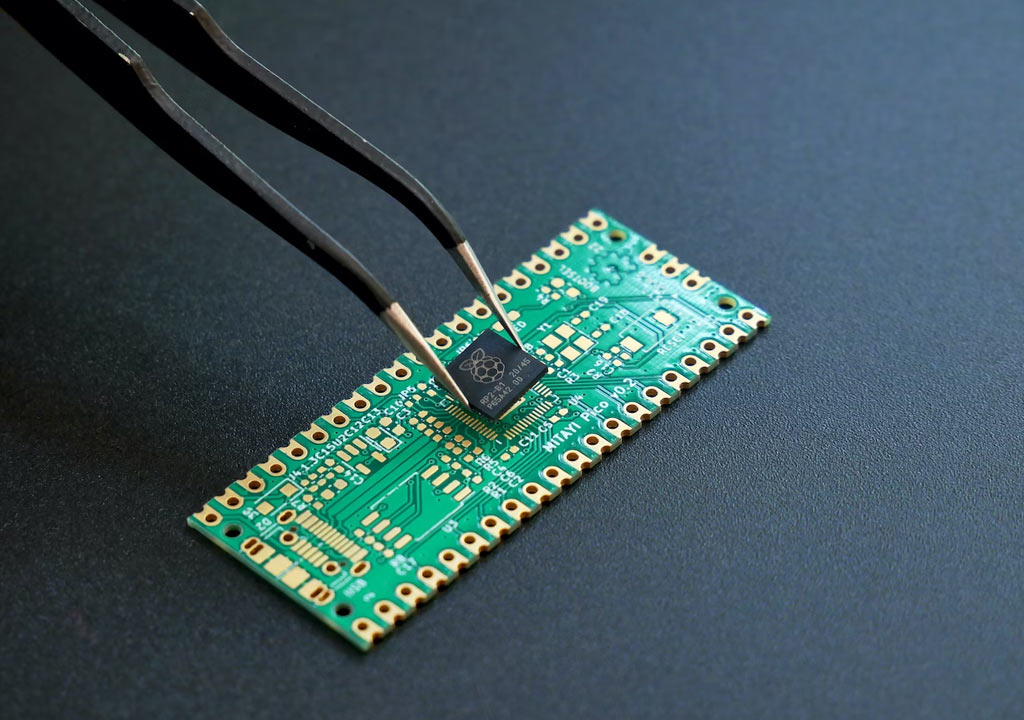

Understanding Complimentary Generic Components: Complimentary generic components are standardized, off-the-shelf parts that serve common functions across a wide range of electronic devices. These components, such as resistors, capacitors, diodes, and connectors, are readily available from reputable suppliers and are compatible with a variety of circuit designs and applications.

Cost Efficiency Through Bulk Purchasing: One of the most compelling advantages of integrating complimentary generic components is the opportunity for bulk purchasing. By procuring these components in large quantities, manufacturers can leverage economies of scale to negotiate favorable pricing terms and reduce per-unit costs significantly. This cost-saving strategy enables manufacturers to allocate resources more efficiently and reinvest savings into research, development, and innovation initiatives.

Streamlined Supply Chain Management: Incorporating complimentary generic components into the manufacturing process streamlines supply chain management and reduces dependency on specialized or custom parts. Unlike proprietary components, which may be subject to availability constraints and lead time fluctuations, generic components are widely accessible and can be sourced from multiple suppliers, ensuring continuity of production and minimizing supply chain disruptions.

Enhanced Quality and Reliability: Contrary to misconceptions, utilizing generic components does not compromise product quality or reliability. On the contrary, many generic components undergo rigorous testing and certification processes to ensure compliance with industry standards and performance specifications. By leveraging reputable suppliers and adhering to strict quality control measures, manufacturers can maintain the highest standards of quality and reliability in their products.

Flexibility and Versatility in Design: Complimentary generic components offer designers unparalleled flexibility and versatility in circuit design and layout. With a vast array of standard components available, designers can explore creative solutions, optimize circuit performance, and expedite the design iteration process. Additionally, the compatibility of generic components across different platforms and applications facilitates seamless integration and interoperability, enabling manufacturers to meet diverse customer requirements effectively.

Accelerated Time-to-Market: In today’s fast-paced market environment, time-to-market is a critical factor that can make or break a product’s success. By leveraging complimentary generic components, manufacturers can expedite the product development cycle and accelerate time-to-market for new innovations. With readily available components and simplified design processes, manufacturers can capitalize on emerging opportunities and stay ahead of the competition.

In conclusion, integrating complimentary generic components into the manufacturing process represents a strategic approach to unlocking cost efficiency, enhancing quality, and driving innovation in electronic product development. By embracing these components and harnessing their inherent advantages, manufacturers can position themselves for sustained success in an increasingly competitive landscape. At PCB Power, we are committed to empowering manufacturers with the tools and resources they need to thrive in today’s dynamic marketplace. Contact us today to learn more about our comprehensive range of complimentary generic components and how they can transform your manufacturing operations.